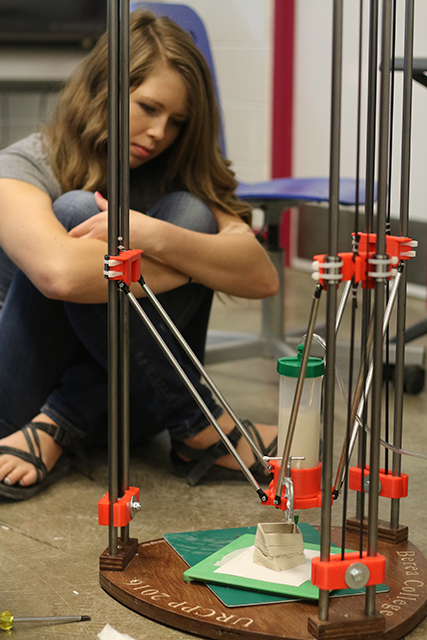

The ceramic delta printer works in a similar manner to the FDM printer where a layer of clay is deposited on to the printer bed. Once a layer is printed, the print head then moves up sightly before printing another layer. The finished piece is then removed from the print bed and further traditional completion of the piece (including firing and glazing) happens.

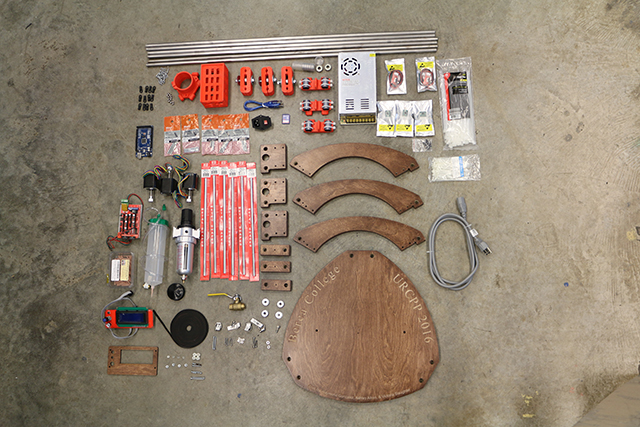

The Ceramic Delta Printer can be either purchased or built. Here, you see the total components that are necessary to build the Ceramic Delta Printer. If you notice, many of the pieces needed are produced on the FDM printer (red). For more information, please see the Prototyping: Process section of this website.